We develop individual software solutions for your robot systems

We develop individual operating- and visualisationsolutions for the smartPad

We plan and develop robot software for almost every process and every technology

We are now ISO 9001 certified and can now officially show that we stand for continuous quality.

Our apps are specially designed for your needs

KRC2/4 App

Version 1.1.20

Price on request

Windows App

Version 2.0.20

FREE

for OrangeEdit

Version 2.0.20

€ 159.-

Windows App

Version 1.2.0

Price on request

KRC4 App

Version 1.2.11

€ 359.-

KRC2/4 App

Version 1.2.0

€ 129.-

KRC4 App

Version 3.1

€ 1190.-

KRC2/4 App

Version 1.0.1

€ 129.-

KRC4 App

Version 1.0.6

€ 189.-

KRC4 App

Version 1.1.12

€ 299.- | € 349.-

KRC4 App

Version 1.0.17

€ 189.-

KRC4 App

Version 1.0.4

€ 119.-

KRC4 App

Version 1.0.4

FREE

KRC4 App

Version 1.0.5

FREE

KRC4 App

Version 1.0.5

FREE

Windows App

Version 1.2.6

*All prices in EUR excl. VAT and shipping costs.

“Perfection is finally attained not when there is no longer anything to add, but when there is no longer anything to take away.”

Antoine de Saint-Exupéry, Terre des Hommes

A small pullout of our various projects

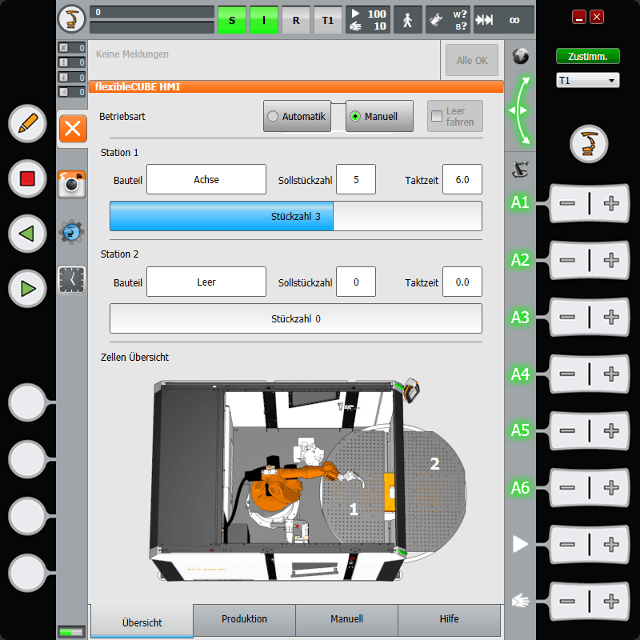

For the modular welding cell -KUKA flexibleCUBE-, OrangeApps has developed an operating and visualization software that is completely integrated into the robot control system.

A setup wizard guides the operator through component and fixture setup.

The production overview shows statistical data on production, the current job, consumption values and much more.

Service and maintenance displays together with online operating and maintenance instructions increase the availability of the system.

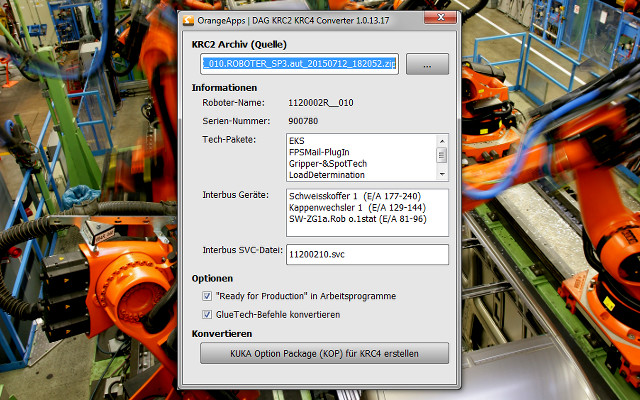

Gradually, at non-production days, 'old' KRC2 robots are exchanged for new KRC4 robots at Daimler in Düsseldorf.

Due to the different architecture, especially for bus systems, OrangeApps developed software that analyzes KRC2 archives, converts data and creates a WorkVisual (KRC4) options package.

In addition to the entire parameterization of the robot, the resulting option package also contains all work programs and a preconfigured bus project. Of course, the conversion of the 'old' coordinates of the non-absolutely accurate KRC2 robots into the absolutely accurate robot model of the KRC4 is also included.

This converter software can reduce the time from first power up to the fully commissioned robot (ready to test the motion programs) to ~ 30 min.

This high degree of automation allows a very short window of time to exchange robots.

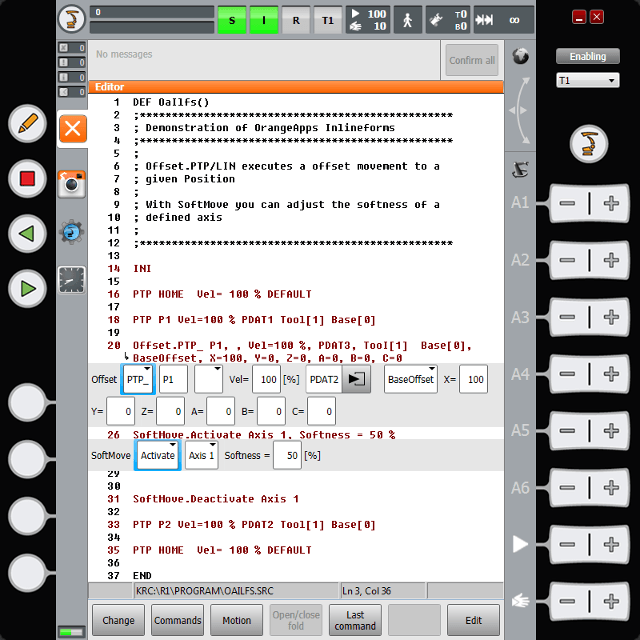

Inline forms facilitate and speed up the programming of a robot.

Clear design, self-explanatory terms and the ability to check values entered make inline forms particularly user-friendly and therefore suitable for operators without deep system knowledge.

OrangeApps develops inline forms to suit every requirement.

The inline form 'Offset' allows to execute a PTP or LIN movement relative to an already taught position. In addition to the data for the offset itself (X, Y, Z, A, B, C), the user can define the reference system (tool or base) as well as the motion parameters (PDAT).

The inline form 'SoftMove' makes it possible to switch specific axes 'soft'. Thus, axles can be controlled 'floated' e.g. insert a component into a fixture without transferring clamping forces to the system through an inaccurate position.

While in the past it was often a question of replacing human work with robots, today the robot often works acts as an assistant next to the worker.

OrangeApps' intelligent and intuitive software complements innovative hardware to simplify operation, integrate systems better, and empower people to work more efficiently with complex systems.

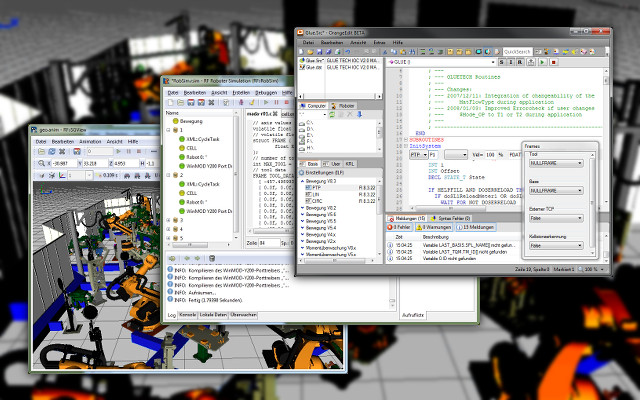

With the help of virtual commissioning (VIBN), the PLC and robot programs can be programmed and tested in advance by the software-related mapping of the real system.

Together with our partner EKS InTec, we are constantly optimizing the workflow in order to merge the real and virtual world. By connecting our OrangeEdit to RobSim (EKS InTec) to simulate the robot programs, the robot programmer works with familiar software directly into the virtual world.

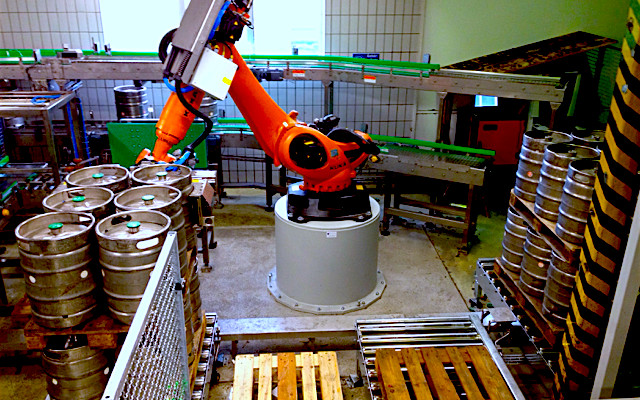

Together with the machine manufacturer Federspiel, we develop intelligent dis- / palletizing robot systems for the food industry.

For depalletizing various KEG variants, we rely on 3D scan technology and a dynamic motion strategy of the robot.

Other features of these systems are:

- Palletize and depalletize up to 180 barrels / hour

- any barrel types from 15 l party to 50 l stainless steel or plus KEG

- configurable pack pattern

- automatic pallet inspection

- easiest operation

- parameterizable, thus short integration times

“Design is not just how it looks or feels. Design is how it works.”

Steve Jobs, The Guts of a New Machine

We are proud to be a team with so much different expertise and experiences

At OrangeApps we have a clear mission - make the robotic even smarter. We have a clear imagination, how to achieve this goal. We simplify the handling, integrate the systems better and enable the people the work more efficient with the complex systems. It is about intelligent software and how its specifically use will make your production even more successful.

The key to our success is the ability to boil complex challanges down to an essence, to find inovative solutions and to satisfy with the best usability. This is why we seek persons with a clear analytic mind, intellectual curiosity and fun in implementation - independent to age or origin. Further you have distinct knowledge and experience with relevant object-orientated coding languages, especially in .NET and accordingly development environments like for example Visual Studio. You already could prove your multiannual expertise in profession in diverse projects and commercial applications. Further knowledge in programming of industrial robots (KUKA, ABB, Fanuc) is a benefit, but not necessary.

If you want to accomplish things in a fascinating area of application together with us, we are looking forward to meet you. Send your documents preferably per e-mail.

A little insight into our numbers

It is our pleasure to advise you personally to enter your questions and requirements better.

Bürgermeister-Wegele-Straße 12, 86167 Augsburg, Deutschland

Arnikaweg 1, 87471 Durach, Deutschland

info@orangeapps.de

Tel.: +49 831 5659877

Fax.: +49 831 5659878